Robotics Repair & Preventative Maintenance

Keep Systems Running Smoothly—and Your Production on Track.

When robotic systems fail, the consequences ripple across your entire operation. Assembly lines stop. Material handling halts. Deadlines are missed. Every unscheduled minute of downtime costs you in productivity, revenue, and customer trust.

Industrial robotics aren’t just expensive assets—they’re essential to your daily operations. When they falter, you can’t afford to wait weeks for service or settle for a band-aid fix. You need fast, expert repairs and strategic maintenance that protect your uptime and keep your competitive edge sharp.

At Altech Process and Control, we deliver exactly that.

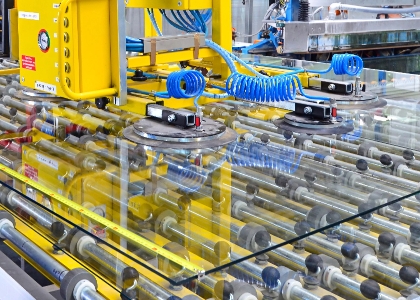

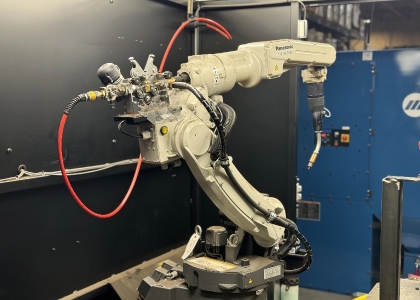

Our Robotic Repair Services:

Robotic arm and actuator repairs

Sensor and feedback system calibration

HMI (Human-Machine Interface) troubleshooting and restoration

System reprogramming and optimization

Servo motor and electrical drive repairs

Whether you’re dealing with a sudden system fault, a mechanical failure, or a confusing error code, our technicians know how to diagnose, repair, and validate your robotic systems—getting you back online quickly and safely

Every moment your robotic systems are offline risks:

The True Cost of Robotic Downtime:

Lost production hours are only part of the cost.

The longer you wait, the bigger the problem becomes.

Every moment your robotic systems are offline risks:

Missed delivery deadlines

Increased labour costs for manual workarounds

Wasted material or incomplete production runs

Disrupted supply chains

Damage to customer relationships

Too often, facilities only think about robotics maintenance after something goes wrong. But smart manufacturers know the real secret:

Proactive maintenance saves time, money, and stress.

Our Preventative Maintenance Programs help you:

Identify wear-and-tear issues early

Catch servo drift, arm misalignment, or actuator fatigue before failures happen

Update firmware, recalibrate systems, and optimize motion control settings

Reduce emergency repairs and unplanned downtime

Extend the life of your investment by years

With regular inspections, testing, and service, your robotic systems stay faster, safer, and more efficient for longer.

Our 5-Step Robotics Repair and Maintenance Process

Diagnose and Troubleshoot

We systematically identify electrical, mechanical, and programming faults.

Source or Fabricate Parts

Need a hard-to-find motor, sensor, or actuator? We track it down—or engineer a retrofit solution.

Repair and Reprogram

Our team repairs components, recalibrates systems, and optimizes robotic functionality.

Validate and Test

We don’t just “hope” it works. Every repaired robot undergoes rigorous testing under real-world conditions.

Plan for Preventative Maintenance

We help you set a schedule for maintenance checks that fit your production cycle.

Why Choose Altech for Robotic Repairs?

Fast On - Site Response

We get you back up and running quickly.

Deep Expertise Across Robotic Platforms

From legacy systems to the latest automation tech.

Cost - Effective Solutions

We repair and optimize before suggesting costly replacements.

Hands - On, Human Service

We don’t send you to a call center—we send technicians to your floor.

Preventative Maintenance Pros

Extend your system’s life, improve safety, and protect your production targets.

Industries We Serve with Robotic Support:

Don’t Let a Single Fault Bring Your Entire Line Down

Partner with Altech Process and Control for expert robotic repairs and proactive maintenance that keeps your facility moving.