Emergency Industrial Machine Repair

When Every Minute Counts, We Deliver Solutions—Fast.

When your CNC machine, robotics system, or plasma cutter fails, it’s not just an inconvenience—it’s a full-blown crisis. Production stops. Orders are delayed. Costs skyrocket. Every hour lost could mean missed deadlines, frustrated customers, and lost revenue. Waiting weeks for an OEM technician to maybe show up isn’t a solution—it’s a gamble you can’t afford to take.

At Altech Process and Control, we specialise in fast, expert emergency machine repair services that keep your business moving. Our skilled technicians show up quickly, diagnose the root cause of your problem, and deliver real solutions—often getting you back online before an OEM service team would even return your call.

When you need answers, not excuses—call Altech.

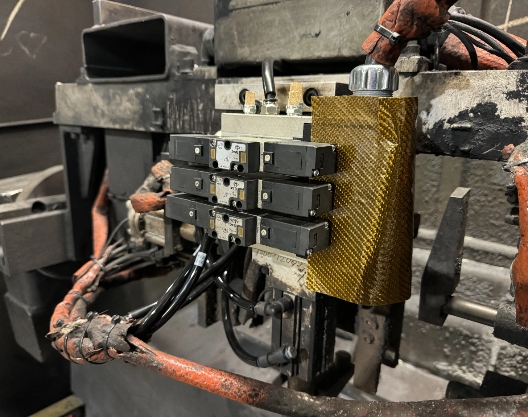

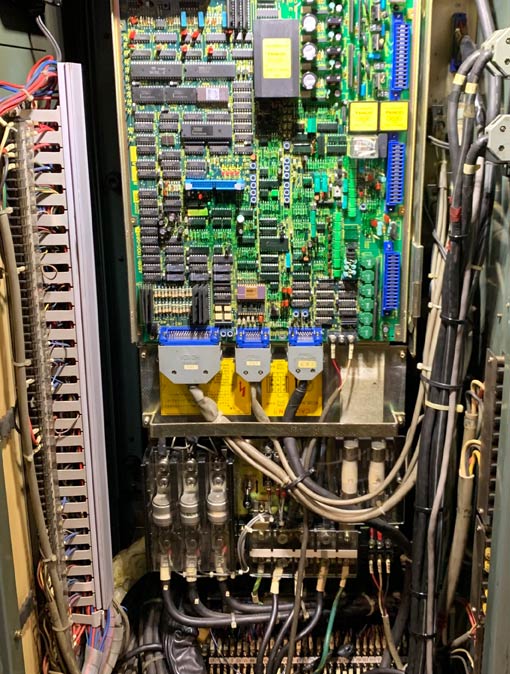

BEFORE

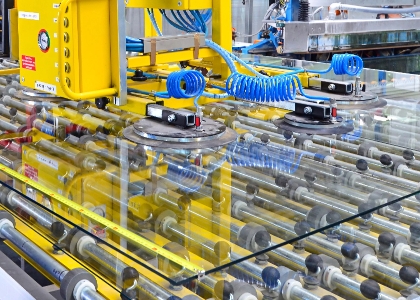

AFTER

We Specialise In:

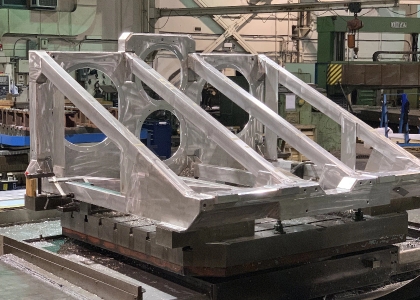

CNC machine breakdowns

Plasma cutting system issues

Servo motor failures

Welding system failures

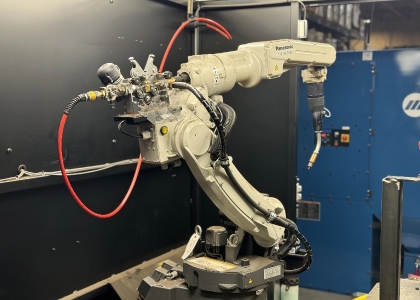

Robotic system malfunctions

Whether it’s a critical sensor failure, a damaged drive, or an unexpected control system error, our team knows how to get to the root of the problem—and get you back up and running quickly and safely.

Our Proven 5-Step Repair Process

When every second matters, you need a team that works systematically to solve the problem—not just patch it.

Diagnose Machine Issue

Advanced diagnostics and systematic troubleshooting identify the exact cause of the failure.

Source and Order Required Parts

We efficiently locate and procure replacement parts, including rare and obsolete components most suppliers can’t get.

Install and Retrofit Components

New parts are installed or retrofit solutions are engineered when standard replacements aren’t available.

Test and Validate Operation

We don’t just fix it—we rigorously test and validate the system to ensure reliable operation before signing off.

Perform Preventative Maintenance

We finish each emergency repair with a preventative maintenance check—helping you avoid another unexpected shutdown.

Why Choose Altech for Emergency Industrial Machine Repair?

Faster Than OEM Response Times

We can often be on-site within 24 hours—because we know your operation can’t wait.

No Waiting Weeks for Parts

Our extensive supplier network and expertise with obsolete systems means we find solutions others can’t.

Experts in Troubleshooting Complex Systems

From new CNCs to legacy robotics, our team brings real-world experience and hands-on skill to every emergency.

Cost-Effective Repairs

Our solutions focus on repairing and retrofitting whenever possible—saving you tens of thousands compared to full replacements.

Cross-Industry Experience

We support operations across heavy steel manufacturing, fabrication, sheet metal production, plastics, glassworks, and more.

Human Service. Real Answers.

When you call Altech, you get a human on the line—ready to help. No endless call centers. No excuses.

Industries We Support:

Don’t Let One Breakdown Bring Your Entire Operation to a Halt.

When failure strikes, you don’t have time for excuses—you need action. Altech Process and Control is your trusted partner for fast, reliable, emergency machine repair services in British Columbia.