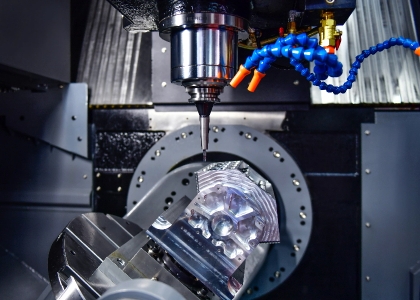

CNC Machine Repair & Upgrades

Save Your CNC. Save Your Bottom Line.

Your CNC machines are the backbone of your operation. When a controller fails, a drive shorts out, or a system grinds to a halt, everything else falls behind schedule—and the costs add up fast.

Replacing a CNC controller or full system can cost upwards of $50,000 or more—and that’s before factoring in the lead time, installation delays, and lost productivity.

But here’s the good news:

In most cases, you don’t have to replace your CNC. You just need the right team to repair, upgrade, and optimize it.

At Altech Process and Control, we specialize in extending the life of CNC machines through expert repair, retrofitting, and preventative maintenance. We help you avoid unnecessary replacements, cut costs dramatically, and keep your operations running at full speed.

When others tell you to replace your system, we find a better way.

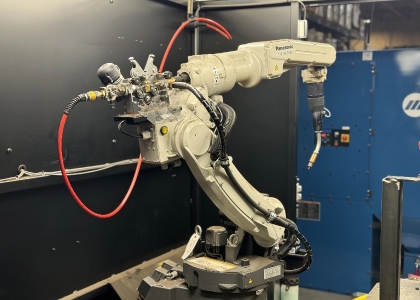

What We Repair, Replace, and Upgrade:

CNC controllers (all major brands)

Servo and spindle drives

Operator interfaces and HMI screens

Motion control systems

PLC-integrated CNC platforms

Feedback systems (encoders, resolvers)

Whether your machine is new, aging, or considered “obsolete” by the OEM, we can often repair or retrofit the system for a fraction of the replacement cost—and in a fraction of the time.

Our Approach to CNC Repair and Upgrades

When you call Altech for CNC support, we follow a proven, efficient process:

Full System Diagnosis

We perform an in-depth analysis of your CNC system, using advanced diagnostic tools and years of hands-on experience to quickly pinpoint the problem.

Source Replacement Parts

We maintain strong relationships with suppliers for both current and legacy CNC parts, enabling us to source rare or discontinued components when necessary.

Repair or Retrofit

We rigorously test the repaired or upgraded system to ensure full functionality, precision, and reliability under real-world operating conditions.

Test & Validate

Before we wrap up, we perform rigorous system testing to ensure operational reliability and precision.

Preventative Maintenance

Once your CNC is operational again, we provide preventative maintenance services to identify potential future issues—and help you avoid another costly shutdown.

Cost Comparison: Repair vs. Replace

Repairing and upgrading isn’t just the smart choice—it’s the strategic one.

REPLACE

New CNC Controller

$50k

Long Lead Time

Reprogramming Required

Full Re-Commisioning

REPAIR

Refurbishing Existing Controller

$10–$15k

Short Lead Time

No Reprogramming

No Re-Commisioning

SAVINGS OF UP TO:

$35,000

Why Choose Altech for CNC Machine Repair?:

Significantly Reduce Downtime

Save Tens of Thousands in Replacement Costs

Experience with Legacy and Modern Systems

Hands - On, Human Service

Preventative Maintenance Expertise

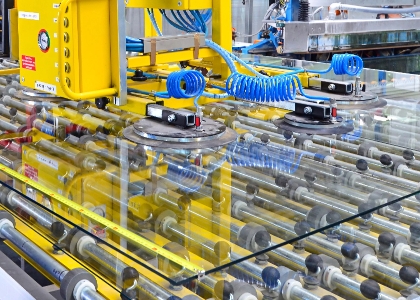

Industries We Support with CNC Repair:

Don’t Let a CNC Breakdown Grind Your Business to a Halt.

Trust Altech Process and Control to restore your CNC system—and your production schedule.

Repair smarter. Upgrade better. Save bigger.