When it comes to running a safe and productive shop, machine safety can’t be something you only think about after an incident. The reality is, even the best equipment becomes dangerous if it is not properly guarded. That is where the right machine guarding solutions come in.

Good guarding protects your people, keeps your production line moving, and saves you from costly downtime or compliance headaches. But how do you know if your setup is doing the job? If you are seeing any of the signs below, it is time to take a closer look.

1. Frequent Near-Misses or Close Calls

Every shop has stories about the “almost” accidents. Someone’s glove got caught for a second, or a worker had to yank their hand back just in time. It is easy to brush these off when no one gets hurt, but they are flashing warning lights telling you something is wrong.

If people are working too close to moving parts, or if they are finding ways to reach around existing guards, that means your current protection is not enough. Near-misses are not just bad luck. They are signs of weak points in your system. Proper machine guarding solutions take those weak spots away, so operators do not have to rely on reflexes or luck to stay safe.

2. Outdated or Missing Safety Features

Walk through your shop and look at your equipment. How many of those machines have guarding that is dented, cracked, or just plain missing? How many are running with guards that were designed decades ago, before modern standards were put in place?

This is a common issue in Canadian manufacturing shops. Many older machines were built to last, but their safety features are far behind what today’s CSA standards and provincial OHS regulations require. Sometimes guards have been taken off completely because they “get in the way.”

That might keep production moving in the short term, but it is an accident waiting to happen. Updating or retrofitting with proper machine guarding solutions gives you modern protection that does not slow down operations. The best designs actually improve workflow by reducing the chance of breakdowns, jams, or injury-related downtime.

3. Rising Injury Rates or Safety Incidents

If your incident log is filling up, you cannot ignore it. Even one injury tied to machinery should be taken seriously. Injuries do not just cost you lost time on the floor. They raise your WCB premiums, hurt morale, and can even damage your reputation with clients and potential hires.

Often, when shops start to see a pattern of injuries, the problem comes back to poor guarding. Maybe operators are exposed to pinch points. Maybe the barriers in place are flimsy and easy to move around.

Better machine guarding solutions are built to eliminate those hazards. By addressing the root cause, you reduce injuries, cut costs, and build a safer culture on the floor. People work more confidently when they know the equipment is properly protected.

4. Complaints or Concerns from Employees

Here is the thing: your operators see risks long before management does. They are standing at the machines all day. If they are telling you a piece of equipment feels unsafe or pointing out where they have to put their hands too close, listen to them.

Workers who do not feel safe will either find ways to cut corners, or worse, stop speaking up altogether because they feel no one is listening. Both scenarios can lead to disaster.

When you respond to concerns with better machine guarding solutions, you show your team that safety is not just lip service. It is a real commitment. That builds trust and gets everyone on board with the changes you are making.

5. Trouble Staying Compliant with Canadian Standards

In Canada, machine guarding is not optional. CSA standards and provincial OHS regulations set clear requirements for guarding dangerous equipment. WorkSafeBC, for example, outlines exactly how equipment must be guarded to protect workers. Other provinces have similar rules.

If you are having a hard time keeping up with these requirements, or if inspections have flagged issues in your shop, that is a sign you need help. Non-compliance can result in fines, stop-work orders, or even legal action if an injury occurs.

The right machine guarding solutions keep you inspection-ready and in line with regulations. That means less stress during audits and more time focused on production.

Why Machine Guarding Solutions Are Worth the Investment

It can be tempting to think of guarding as just another cost, especially if you are running on thin margins. But the truth is, good guarding pays for itself. Here is why:

- Fewer injuries mean fewer WCB claims, less lost time, and lower premiums.

- Less downtime because you are not stopping production after accidents.

- Stronger compliance so you avoid fines and stay focused on your work.

- Better morale when employees know their safety comes first.

Instead of patching up old guards or hoping for the best, investing in the right solutions makes your operation stronger in the long run.

How Altech Helps with Machine Guarding Solutions

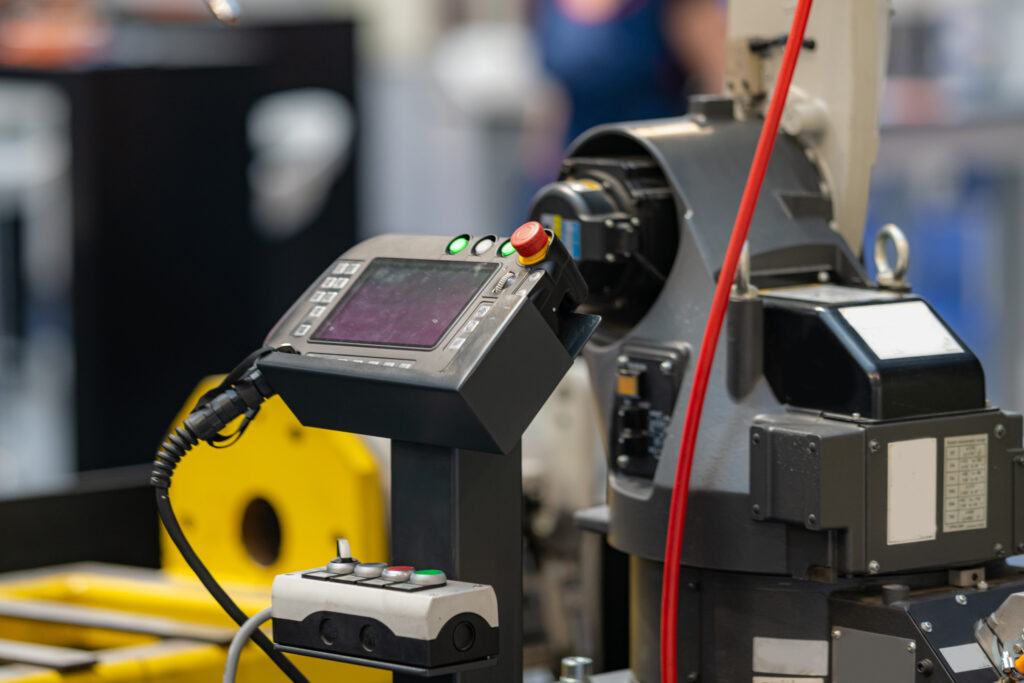

At Altech, we know machine safety is not one-size-fits-all. Every shop is different, and every machine has its own risks. That is why we do not just drop in generic barriers. We work with you to design and integrate guarding that fits your equipment and your workflow.

Whether you need retrofits on older machines, upgrades to meet CSA standards, or new guarding systems designed from scratch, we bring the experience and technical know-how to get it right. Our focus is always on solutions that protect people without slowing down your production.

If you are seeing any of these signs in your shop, such as near-misses, outdated guards, rising injury rates, employee complaints, or compliance problems, it is time to act. The risks are too high to ignore.

Better machine guarding solutions are not just about ticking boxes on a safety checklist. They are about protecting your people, keeping production on track, and making sure your business can grow without preventable setbacks.

Ready to upgrade your machine guarding solutions? Contact Altech today to talk about a custom plan that works for your shop.